Contact Us

Consulting Hotline:029-89587411

Sales Hotline:13659211921

Transformer Contacts:13572270823

Email:changkai67@163.com

Enterprise QQ:3419376426

Address:Xi'an Science and Technology Second Road, Shaanxi Province

Henan Pharmaceutical Factory Project

Hits:279Timer:2019-09-04

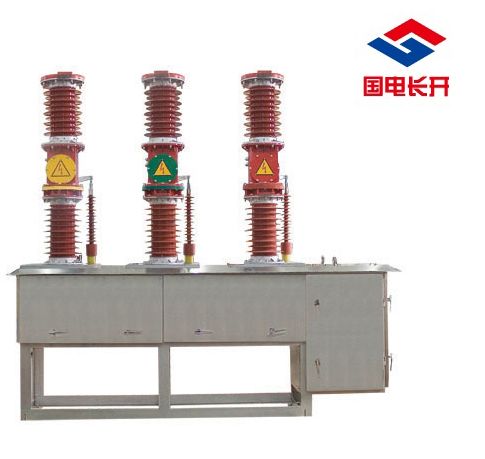

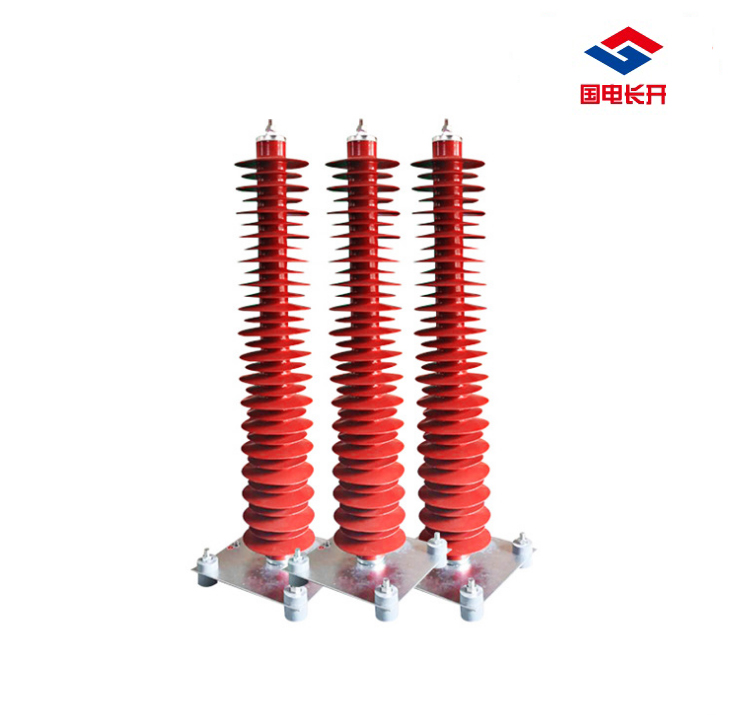

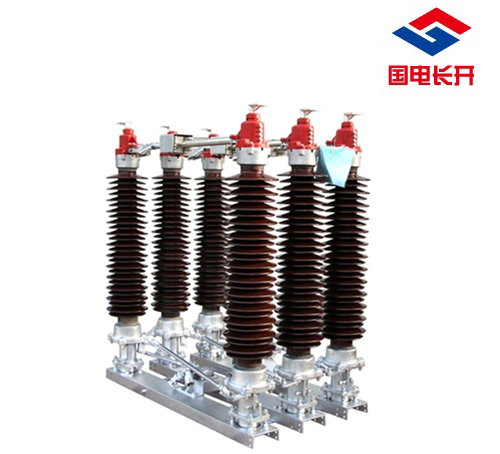

LVB-35, 66, 126KV series oil-immersed inverted vertical (oil-immersed inverted) current transformers for power lines rated at 35KV-550KV, rated frequency 50HZ, proportionally convert the current value on the primary line into a standard current The value (1A or 5A) provides current signals for electrical measuring instruments, meters, and protection and control devices.

LVB-35 (LVB-110) oil-immersed inverted current transformer This series of products mainly consists of expander, oil storage cabinet, primary winding, body, porcelain sleeve, base and junction box, etc. In the core housing of the part, the main insulation is made of oil-paper capacitive insulation structure. The expander can adjust the volume change of the oil caused by the temperature change, and the oil level indicator is arranged on the expander. The grounding plate is provided on the lower part of the product for product grounding, and a drain valve is provided for oil sampling. The terminal block in the junction box is used to ground the terminal of the secondary junction box.

The LVB type current transformer is oil-paper insulated and inverted structure. The head casing is made of cast aluminum alloy with a secondary coil inside, and a primary conductive rod passes through the middle of the core casing of the secondary coil. The main insulation consists of two parts: head insulation and straight rod insulation. The straight rod part is a pressure equalization sleeve composed of several capacitive screens. The secondary winding is assembled in the secondary shielded aluminum alloy core casing, and the secondary lead wire is led to the junction box on the base through the lead conduit for the user to use. A stainless steel expander is placed on the top of the product head to release internal pressure. The outer insulating porcelain sleeve is poured together with the lower oil storage cabinet and the base. The connection between the head casing, the flange and the base is mostly sub-arc welding, and no mechanical connection such as bolts is used, and the sealing performance is reliable, basically Solved the problem of oil leakage in oil-immersed products.