Contact Us

Consulting Hotline:029-89587411

Sales Hotline:13659211921

Transformer Contacts:13572270823

Email:changkai67@163.com

Enterprise QQ:3419376426

Address:Xi'an Science and Technology Second Road, Shaanxi Province

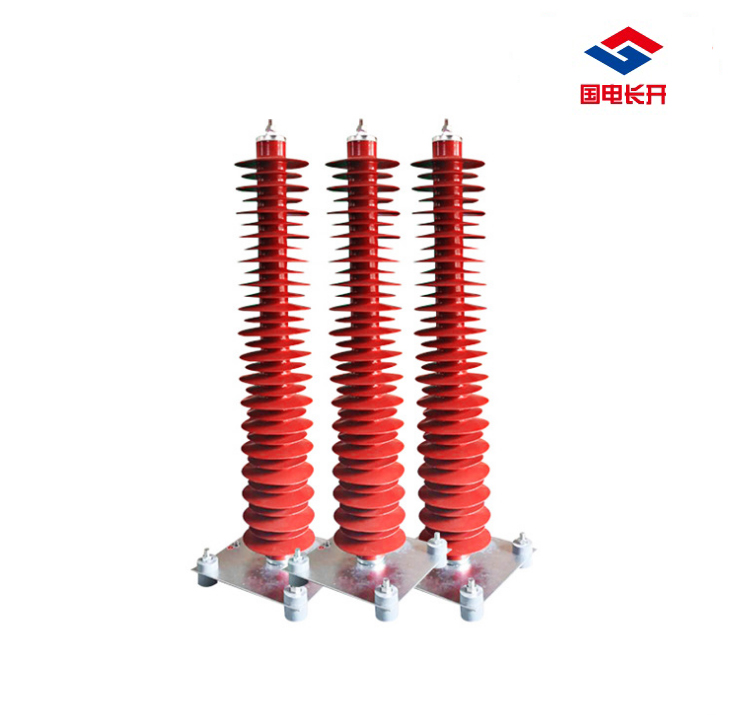

LGB-126W3 dry current transformer

Hits:38Timer:2019-09-06

一、 Overview

LGB-126 dry current transformer, 110KV dry current transformer consists of main components such as carrier fluid, capacitor core, outer sheath, shed, secondary winding, bottom box and end structure. The bottom box is provided with measuring terminals, which are opened for partial discharge and dielectric loss factor measurement, and should be reliably grounded during normal operation.

LGB-110W3 (LGBJ-110W3) outdoor single-phase organic composite insulated dry current transformer for current, energy measurement and relay protection in 35-220KV, 50 or 60HZ power system. Follow GB1208 "Current Transformer", environmental pollution level: II, III, IV. LGB-110W3 (LGBJ-110W3) dry current transformer is organic composite insulation, silicone rubber umbrella skirt insulation, electric field distribution is uniform, partial discharge is small and stable, and dielectric loss is small. By changing the wiring pattern in the unshielded cover on the product, the series-parallel connection can be conveniently realized, thereby changing the current ratio.

LGB-110W3 (LGBJ-110W3) Dry Current Transformer This product is oil-free, porcelain-free and air-free. The product basically does not require maintenance, and the capacitance and dielectric loss factor of the main body can be measured every 2-3 years. LGB-110W3 (LGBJ-110W3) dry current transformer product base uses Dacromet + spray paint double-layer anti-corrosion, beautiful and anti-corrosion performance. Fasteners and nameplates are stainless steel.

product structure

The LGB-110W3 (LGBJ-110W3) series of current transformers are composite insulated dry vertical structures. The composite insulated dry current transformer series is a new type of insulating material and has a new insulation structure of current transformer. It is insulated by PTFE film and silicone rubber instead of traditional oil paper, SF6 gas and epoxy resin insulation structure. The structure is relatively novel, basically requires no maintenance, and has the advantages of strong anti-fouling ability, non-combustible, non-explosive, and the like, and is suitable for places with high safety requirements.

LGB-110W3 (LGBJ-110W3) outer insulation: the outer insulation of the product is made of silicone rubber insulation material. See “Inspection and Maintenance” for details on the surface maintenance of silicone rubber. LGB-110W3 (LGBJ-110W3) primary terminal block: The primary terminal block is located at the head of the transformer, and their shape and size are subject to contract and special installation requirements. The primary winding is divided into two forms, one is a single ratio. In this form, if the user requires a multi-ratio, this single-ratio form can achieve the multi-ratio requirement through the secondary winding, that is, twice. The method of winding the tap is realized; the other is that the primary winding is divided into two sections, four in total, and the current ratio is changed by changing the wiring manner of the connecting piece once, and the requirement of the user variable ratio is completed by one time or once and two times. This structure has two types of wires and copper (aluminum) rows. It can also be stated when ordering.