Contact Us

Consulting Hotline:029-89587411

Sales Hotline:13659211921

Transformer Contacts:13572270823

Email:changkai67@163.com

Enterprise QQ:3419376426

Address:Xi'an Science and Technology Second Road, Shaanxi Province

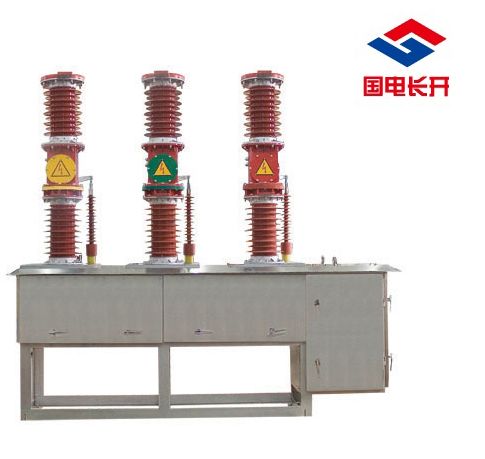

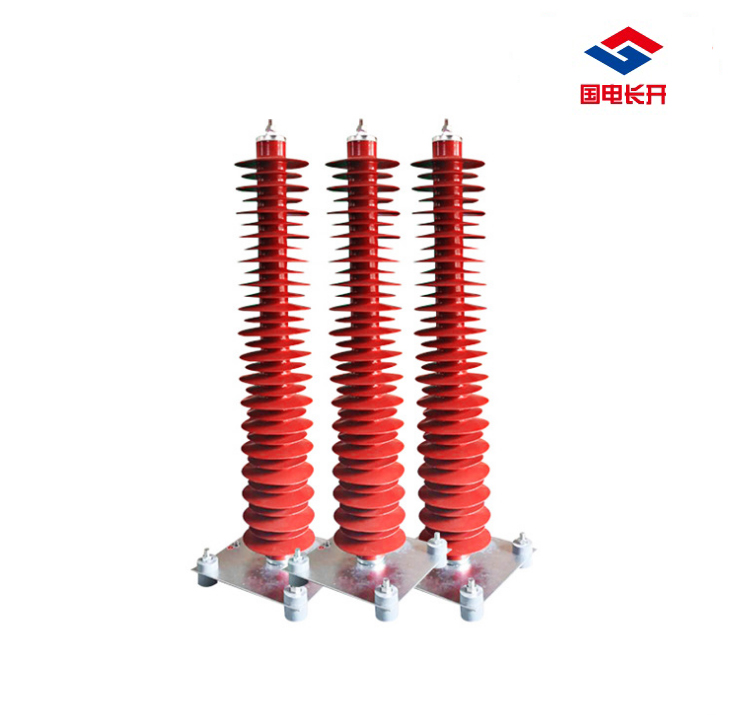

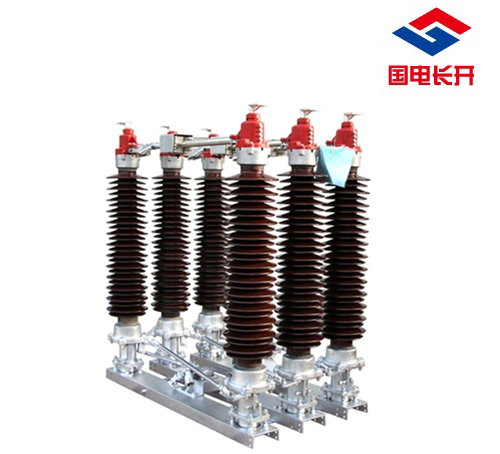

LVQB-110 current transformer

Hits:41Timer:2019-09-06

Product basic structure:

The overall structure of LVQB-110 sulphur hexafluoride current transformer is inverted, mainly composed of three parts: shell, porcelain sleeve and base. The housing is located at the top of the product, and the primary winding and the secondary winding are respectively mounted in the housing; the housing is equipotential with the primary circuit, and is insulated from the base by the porcelain sleeve; the primary winding passes through the middle of the secondary winding, and hexafluoride is used between them. The sulfur gas is insulated. The secondary winding is fixed in the casing through the insulating cylinder; the secondary winding lead is connected to the secondary connecting terminal in the base through the metal shielding tube in the porcelain sleeve for the user to connect the measuring or protecting load. The base is provided with an adsorbent, a secondary wiring plate, a sulfur hexafluoride pointer type density relay, and the like.

The primary winding of the LVQB-110 type sulphur hexafluoride current transformer is a double-turn series-parallel structure. For the structure in which the primary winding is double-turned, serial and parallel switching can be performed, and the series-parallel structure takes into account the conduction of the casing, and the small-to-variance ratio is obtained in series, and the large-to-variance ratio is obtained in parallel (see the tail page appearance and the installation diagram). Series and parallel diagram). When connecting in series, use the U-shaped baffle to connect the terminal block on the conductive tube in the P1 end and the P1 end cover (connected to the outer conductive tube of the P2 end). When connecting in parallel, use the single-input terminal block to connect the outer conductive tube of the P1 end. The upper wiring board and the inner conductive tube are firmly connected, and the U-shaped baffle (connecting with the barrel and the outer conductive tube) of the P2 end and the wiring board on the inner conductive tube are firmly connected by the primary outgoing wiring board. The load can be connected to the corresponding secondary terminal according to the needs of the secondary circuit.

Product dimensions (length × width × height)

Conventional type: 1150×600×2309mm;

Anti-fouling type: 1150×600×2489mm;

Note: The length of the product can be lengthened by 100, 200 and 300mm according to the special requirements of the secondary winding.

1.2 product weight

500kg